What issues are warehouse managers facing – and how can industrial drones help?

We know it might sound crazy at first, but what if I told you drones flying around your warehouse can help you overcome a number of daily issues and challenges you might face?

They can work around the clock and take away the tedious task of inventory counts while you and your staff crack on with the bigger operations. Worth a read?

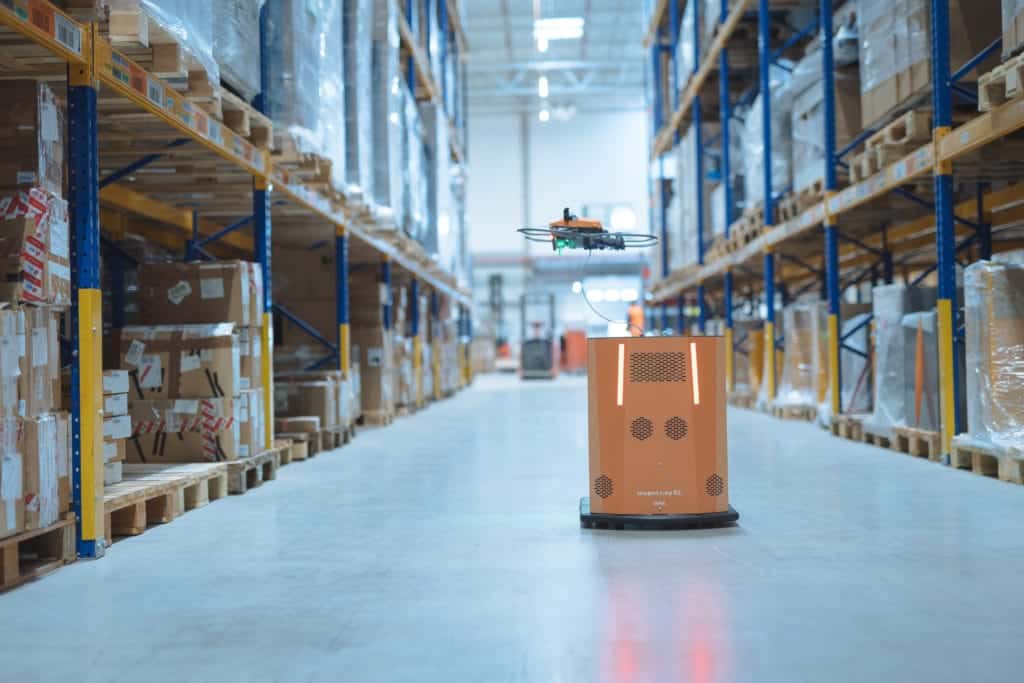

We’ve been going full steam ahead rolling out the inventAIRy XL solution in warehouses of all shapes and sizes, and with that has come the chance to gain even greater insight into what issues warehouse managers face.

The issues are pretty consistent across all warehouses and industries, but the extent to which these are problematic varies by individual needs. Fortunately, inventAIRy XL is an excellent solution for all these issues, so you can be sure that, whichever of the following is most appropriate to you, this clever combination of robot and drone will be able to help.

Inventory drones are best suited to facilities that suffer either from inaccurate inventory records, or who find staying on top of inventory with regular manual counts a significant cost implication.

So what are these issues, and how can industrial drones like inventAIRy XL help?

Health & Safety: trying to reduce/eliminate the need for warehouse staff working at height

While you can never fully remove the need for warehouse staff to work at height, industrial drones can considerably reduce the need by automating some of the tasks that require it.

One of those tasks is inventory counts, where staff need to go right to the top of the racks to perform stock takes. Send inventAIRy XL instead – this drone is not scared of heights and won’t fall off a ladder, so companies can be safe in the knowledge that their staff are no longer subjected to unnecessary safety risks.

Efficiency: physical inventory counts are the only way to reliably quantify any discrepancies between the virtual world ( ie. the WMS) and what is actually in stock at any moment in time. But, the process is extremely time-intensive, meaning physical counts tend to be carried out at the absolute bare minimum.

This is a big issue, as the fewer physical checks that are performed, the more chance errors can creep in and compound over time. By automating the process, you can run as many inventory counts as you want – giving you greater confidence that your warehouse and your WMS are on the same page.

Reduce cost for customers: third-party logistics companies (3PLs) sometimes require that the end customers are responsible for conducting the physical inventory counts themselves (usually once a year for statutory audit purposes).

This involves shutting down part of (or all) of the 3PL’s warehouse and deploying dozens of ‘counters’, sometimes for days on end, to do a full wall-to-wall count of their stock. By implementing an automated system like inventAIRy XL, you can remove this expensive headache for your customers. It may even give you the edge when pitching to new customers, too – after all, would you rather use a 3PL who needs you to perform those yearly checks, or one that takes the strain for you?

Empty pallet detection: a big issue we encountered during our travels was that empty pallets often get mistakenly left in the racks. Unless a warehouse operative happens to stumble across this situation, and critically, remembers to record it in the system, the WMS will continue to think that those spaces are not available to receive inbound stock, thus leading to bottlenecks during the put-away process.

On the other hand, inventAIRy XL is able to detect this scenario automatically during its routine missions and notify the warehouse manager immediately of the precise locations (eg. pallet space ‘ABC123’) where an empty pallet is taking up racking space. This allows them to go straight to those locations, remove the empty pallets, and update the WMS to say that those spaces are now available to receive inbound stock.

Conclusion

While every warehouse will experience its unique issues, there are definitely themes that crop up consistently. Industrial drones like inventAIRy XL is able to resolve these common issues (Read more), as well as overcoming all the traditional issues with using drones in warehouses.

Speak to us today if you’d like to arrange a proof of concept and see, within 24 hours, what an impact it can have on your operation.