The integration of warehouse inventory drones represents a significant leap forward in supply chain management, combining tangible efficiency with technological innovation.

This article delves into the traditional methodologies of inventory control, and compares them with the cutting-edge application of drones in warehouse operations. By comparing these two approaches, we throw light on the transformative potential of drone technology in optimising inventory management processes.

Traditional Inventory Control: A Foundation with Limitations

Traditionally, inventory control has been a cornerstone of warehouse management, characterised by manual, human-led stock counts, extensive paperwork, and the inevitable margin for human error. Methods such as physical stocktaking and manual data entry into spreadsheets or basic inventory software have been the norm. These practices, while straightforward, are labour-intensive and prone to inaccuracies, posing significant challenges in maintaining optimal stock levels and real-time inventory visibility.

The manual nature of traditional inventory management systems limits scalability and efficiency, increasing operational costs as businesses expand. Despite these drawbacks, such methods have provided a fundamental, hands-on approach to managing stock levels, laying the groundwork for more advanced solutions.

The Advent of Warehouse Inventory Drones: Redefining Efficiency and Accuracy

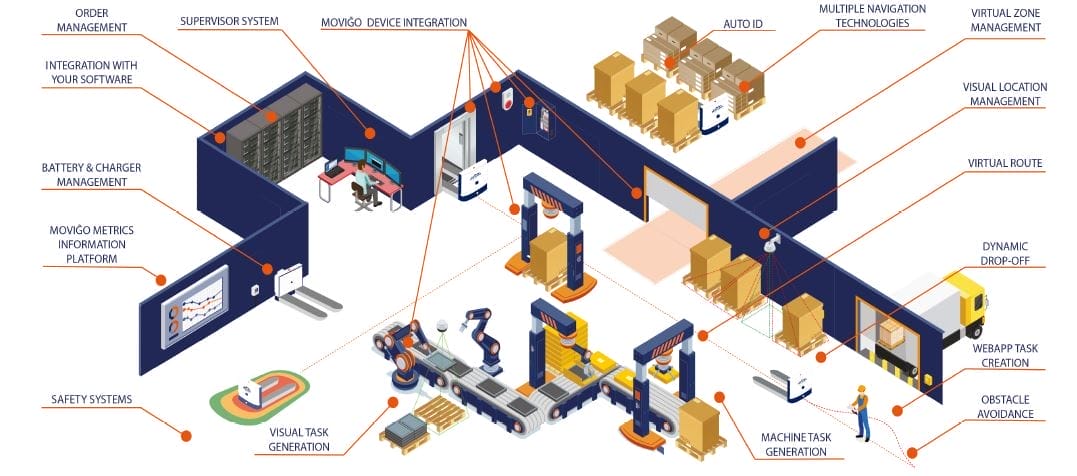

Warehouse inventory drones, equipped with sophisticated cameras and scanning technology, offer a revolutionary solution to the inefficiencies of traditional inventory control. These autonomous flying robots enhance accuracy, speed, and efficiency by automating the data collection process, significantly reducing the likelihood of human error and operational disruptions during stock takes.

One of the most notable benefits of integrating drones into inventory management is their ability to provide real-time data, facilitating immediate insights into stock levels. This capability is crucial for dynamic inventory management, allowing businesses to swiftly adjust to market demands and minimise risks associated with stockouts or surplus inventory.

Drones not only expedite inventory checks but also enable more frequent and less intrusive audits without halting daily operations. Their ability to navigate hard-to-reach areas ensures a comprehensive inventory assessment, surpassing the limitations of manual methods.

Comparative Analysis: Manual Methods vs. Drone Technology

When evaluating manual inventory control against the use of warehouse inventory drones, the benefits of drone technology become crystal clear. Drones outshine manual processes in efficiency, accuracy, and the ability to scale with business growth without a corresponding increase in labour costs. The transition to drone-based inventory control, while initially requiring investment in technology and training, ultimately leads to significant operational advantages and cost savings.

However, embracing warehouse inventory drones involves overcoming perceived challenges such as upfront costs and the integration with existing systems. It is these initial challenges that RAWview help you to overcome, quickly unlocking the inherent benefits—including streamlined operations, enhanced accuracy, and improved inventory visibility—all of which position drone technology as a pivotal innovation in warehouse inventory management.

Embracing the Future: Warehouse Inventory Drones in Supply Chain Management

The shift from traditional inventory methods to the adoption of warehouse inventory drones signifies a critical evolution in supply chain management. This transition aligns with broader trends of automation and digital transformation, promising a future where inventory control is not only more efficient but also more accurate and less dependent on manual labour.

As businesses continue to seek competitive advantages through operational efficiency, the role of warehouse inventory drones will undoubtedly expand, bringing a new era of innovation and optimisation in warehouse inventory management. With the potential to redefine traditional practices, drones stand at the forefront of technological advancements, offering a glimpse into the future of streamlined, effective warehouse operations.

Wrapping Up

The comparison between traditional inventory control methods and the innovative use of warehouse inventory drones reveals a clear path toward operational excellence in supply chain management. While traditional methods have served their purpose, the advent of drone technology offers unparalleled improvements in efficiency, accuracy, and scalability. As the industry continues to evolve, the integration of drones into inventory management practices will play a crucial role in shaping the future of warehouse operations, driving forward the relentless pursuit of optimisation and efficiency.

Revolutionise your warehouse

See our exclusive whitepaper to find out how you can enhance your warehousing and logistics operations