Introduction

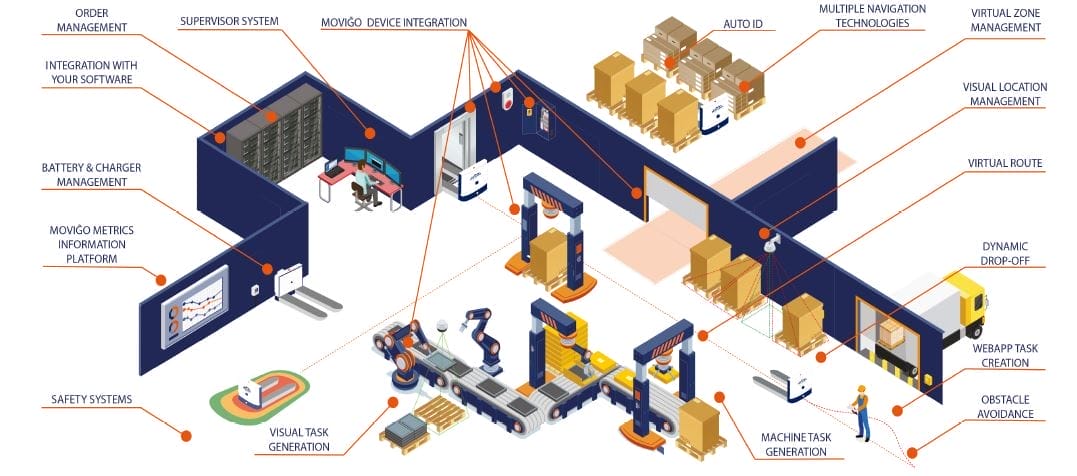

Embracing innovation within warehouse operations has never been more critical than in today’s dynamic market environment. The introduction of advanced warehouse inventory drone technology stands at the forefront of this transformation, offering a significant leap towards operational excellence. This detailed guide is meticulously designed for Automation Management professionals who are on the quest to redefine their logistical operations. It delves into the strategic deployment of drones, aiming to unlock exceptional levels of efficiency, accuracy, and safety. By navigating through the insights provided, professionals can embark on a journey to elevate their warehouse management practices to new heights, harnessing the full potential of drone technology in their operations.

Objective Alignment and Scope Definition

Strategic Alignment with Business Goals

Ensure your warehouse drone project aligns with your organisation’s strategic goals, specifically targeting inventory accuracy improvement, labour cost reduction, and safety enhancement.

Comprehensive Project Scope

Define the project’s scope meticulously, considering inventory types, warehouse dimensions, and challenges like high shelves or hazardous materials, ensuring drone technology can address these effectively.

Detailed Cost Analysis

Investment and Operational Expenditure

Detail the initial costs, including system implementation and software integration. Outline ongoing expenses, such as maintenance, software subscriptions, and staff training, providing a holistic view of financial commitments.

Identifying Cost Savings

Understand and articulate the potential for significant savings through reduced manual labour, minimised inventory losses, and improved safety, drawing attention to labour efficiency improvements and operational cost reductions.

Quantifying the Benefits

Efficiency and Accuracy Gains

Quantify the impact of drones on speeding up inventory processes and enhancing accuracy, illustrating the benefits with real-world data or projections.

Labour Optimisation and Safety Improvements

Discuss how drones allow for strategic reallocation of labour resources and significantly reduce the risk of workplace accidents, linking these outcomes to ROI enhancement.

ROI Calculation and Analysis

Formula for Success

We recommend using an annualised ROI formula for assessing the warehouse inventory drone project. This approach provides a standardised metric that accurately reflects the project’s financial performance over time.

Break-even Point Discussion

Analyse the break-even point, offering insights into when the project will start generating net positive returns, underpinning financial planning and stakeholder communication.

Unveiling the Sources of ROI

Exploring the various sources of ROI in the deployment of warehouse inventory drone technology unveils a broad spectrum of benefits, each contributing to the overarching goal of operational excellence and financial efficiency.

Labour Efficiency: Drones automate routine inventory checks, drastically reducing the time and manpower needed. This shift not only cuts down on labour costs but also unlocks the potential to reallocate human resources to more strategic, value-adding tasks, amplifying productivity and operational effectiveness.

Accuracy Improvements: The precision of drones in inventory management minimises errors in stock, leading to more reliable data for decision-making. Enhanced accuracy reduces costly inventory discrepancies, streamlines order fulfillment, and improves customer satisfaction.

Cost Savings: Beyond labour and accuracy-related savings, drones contribute to reduced operational costs through optimised use of warehouse space and resources. They enable higher storage density and better inventory tracking, which can diminish the need for physical expansions or extra storage facilities.

Safety Measures: Implementing drones significantly lowers the risk of workplace accidents by taking over hazardous tasks such as working at height. This not only safeguards employees but also has the potential to reduce related costs, such as compensation claims and insurance premiums.

Revenue Growth Opportunities: With improved inventory accuracy and efficiency, businesses can offer a faster, more reliable service, enhancing customer loyalty and attracting new clients. This cutting-edge approach directly translates into potential revenue growth through increased sales and market share.

Intangible Advantages: The adoption of drone technology enhances a company’s brand image, positioning it as a forward-thinking, innovative leader in its industry. Furthermore, the reduction in monotonous tasks and the emphasis on safety can significantly boost employee morale and retention, fostering a more motivated and engaged workforce.

Risk Management and Continuous Improvement

Strategic Risk Mitigation

Identify potential risks and articulate comprehensive mitigation strategies, advocating for phased implementation and agile response mechanisms.

Feedback Loops and Technology Updates

Encourage the adoption of feedback mechanisms for continuous process refinement and highlight the importance of staying abreast of technological advancements to sustain operational efficiency.

Conclusion: Elevating Warehouse Operations

This guide serves as a strategic blueprint for Automation Management professionals seeking to leverage inventory drone technology to elevate warehouse operations. By adopting a detailed, structured approach to quantifying the benefits and meticulously planning for implementation and ongoing optimisation, organisations can unlock significant value, enhancing efficiency, safety, and competitiveness in the marketplace.