How to quantify the ROI of warehouse drones

Automating your warehouse inventory counts can help save time and money, increase accuracy and enhance safety, but how do you show an ROI? We’ll walk you through the steps.

Inventory drones are best suited to facilities that suffer either from inaccurate inventory records, or who find staying on top of inventory with regular manual counts a significant cost implication.

If you work in the warehousing and logistics industry, you’ll be familiar with a range of technologies that facilitate automation of various areas of the supply chain. But, are you aware of the next big thing in your world – autonomous drones for inventory counts.

As is the case with the adoption of any new technology, it’s important to determine how the investment will generate quantifiable business value; within an appropriate timeframe; and with minimal operational risk or disruption. It’s these points that we aim to address in this post. But before we dive into that, let’s take a closer look at the ideal candidate for such a solution.

Rack & pallet storage layout

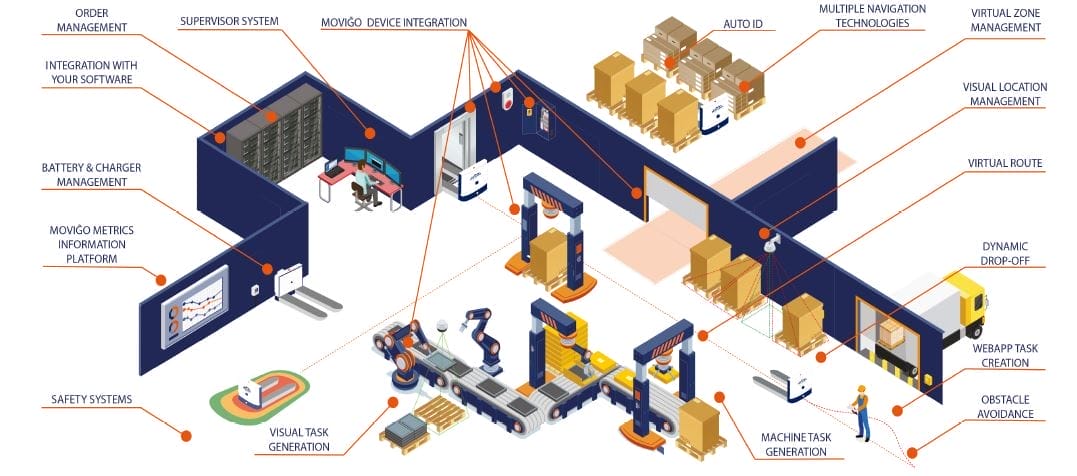

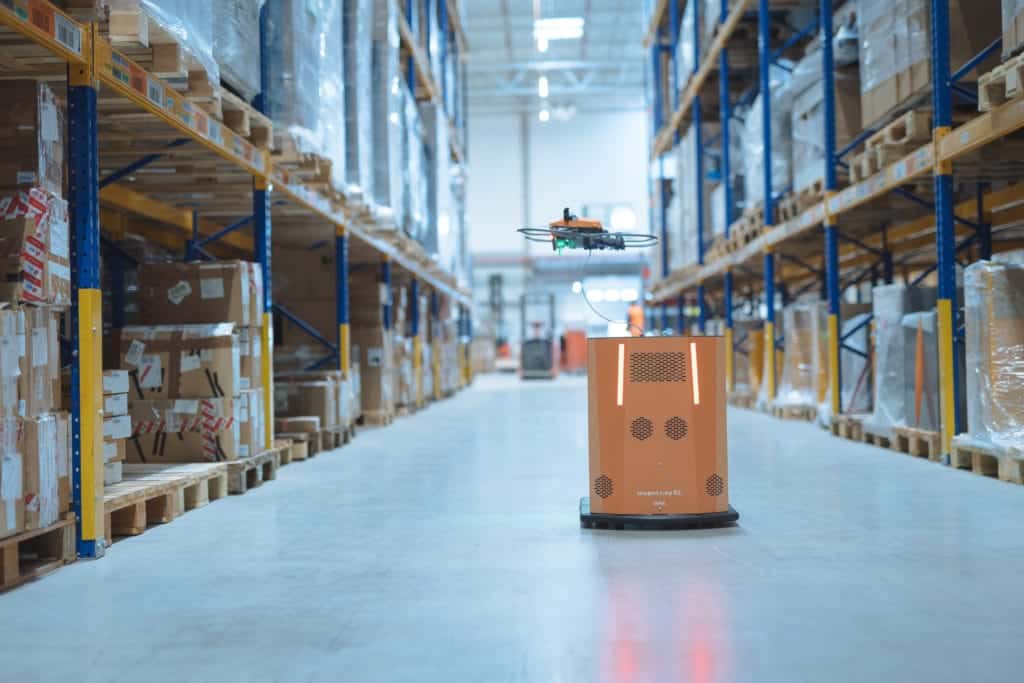

Warehouse drones for inventory counts are designed to replicate the role of warehouse operatives, whose inventory counting methods are to scan the aisle-facing barcodes (or QR codes) of whole pallets. Therefore, the technology is best suited to warehouses that adopt a rack & pallet storage layout, with pallets stored one-deep in their bays. Take a look at the below graphic, which should help you to determine how the technology works.

Suffering from the repercussions of inaccurate/outdated inventory records

The big benefit of an inventory drone solution like inventAIRy XL is that they can work completely autonomously, around the clock. This means that counts can be determined by the optimum frequency and can be done at the time of day (or night) that’s going to cause the least disruption to the normal function of the warehouse.

Furthermore, using machines instead of people removes any human-error factor from the process. The net result of this is that warehouse management teams can now be confident that the inventory records stored in their WMS are a true representation of what’s actually on the shelves.

With all of this in mind, inventory drones are best suited to facilities that suffer either from inaccurate inventory records, or who find staying on top of inventory with regular manual counts a significant cost implication.

Struggling to recruit warehouse operatives

The recruitment challenges brought about as a result of BREXIT are well-known. And the warehousing and logistics sector are at the sharp end of these challenges.

The autonomous nature of warehouse drones means that the low-value, yet business critical task of inventory counts can continue; irrespective of the warehouse’s staffing situation.

A desire to show demonstrable effort to reduce the warehouse’s environmental impact

This is a subject we covered in depth in a previous post, but in a nutshell; inventory optimisation can directly help reduce a warehouse’s carbon footprint. Analysing data to create better forecasts, managing the supply chain more efficiently (e.g. by ordering full truckloads or combining freights) as well as becoming more agile to react faster to the market are all ways that will help you to reduce your business’ carbon footprint. Improving the accuracy of inventory data is the starting point to all of this, and is the exact purpose of inventory drones.

The business value of warehouse drones

So, with the ideal candidate for warehouse inventory drones now determined, let’s take a look at some of the most salient areas of business value realised by adopters of the technology, and points that should definitely be considered when quantifying the ROI of inventory drones:

FINANCIAL VALUE

-

-

- Full-time staff are no longer required to be engaged in inventory counts

- Staff can be redeployed to more productive duties

- Reduced hire costs (or depreciation) of machinery used to allow operatives to count high rack positions

- Shorter shutdown periods

- Less capital tied up in buffer stock

- Lower risk of stockouts (lost revenue)

- Reduced occurrence of mis-shipments

- Lower risk of stock perishability or obsolescence

- Reduced levels of inventory shrinkage

- Audit penalties reduced

- Contributes to meeting your customers’ ‘Scope 3 emissions’ objectives (less chance of losing contracts)

-

STAFF WELFARE VALUE

-

-

- Fewer work-based injuries

- Reduced personnel-related liability

-

Conclusion and next steps

It’s clear that drone technology has a number of compelling arguments for adoption of the use case discussed in this article. But the million-dollar question, I hear you ask is: Will an investment in an autonomous drone solution like inventAIRy XL generate quantifiable business value, within an appropriate timeframe for MY business?

Every business has their own thresholds that must be met to decide if a business case is worth pursuing, so we’ll leave you to answer that question. However, we hope that this post along with our ROI tool might just help you to answer that question!

Like what you’ve read so far? There’s lots more in our logistics whitepaper. Get your free copy at the link below.

Revolutionise your warehouse...

Discover the advantages a drone automation programme can bring to your warehouse & logistics operation.

Ready to speak to one of our experts? Get in touch today.