How accurate inventory management can reduce your carbon footprint

There can be a number of business factors you need to think about in the modern world, costs, efficiency and even your carbon footprint. Automating your warehouse inventory counts can help save time and money, increase accuracy and reduce your carbon footprint. Let us explain how:

Inventory drones are best suited to facilities that suffer either from inaccurate inventory records, or who find staying on top of inventory with regular manual counts a significant cost implication.

Climate change and carbon emissions are getting ever-increasing levels of press coverage (rightly so!), and this will only get more prominent as we near 2030.

With countries across the globe pledging to reduce or eliminate carbon emissions, the onus is now on businesses to work to get their own house in order.

As well as the direct Scope 1 and 2 requirements (company vehicle fuel use and utilities) businesses are also responsible for Scope 3 emissions based on purchased goods and services, business travel, employee commuting and, crucially, transportation and distribution (up- and downstream).

That will have huge implications for warehouse and logistics companies. Not only will warehouse operations need to reduce costs as part of their own Scope 1 and 2 commitments, any companies outsourcing their inventory storage will need – as part of Scope 3 – to ensure their chosen provider is doing their part, too.

So the question warehouse operators (and their clients) will be asking is…

How do you manage the carbon footprint of your supply chain?

A simple place to start for most businesses is to reduce emissions from buildings and company vehicles. But Scope 3 requirements mean businesses need to optimise the operational decisions they make around inventory management, production, and transportation – and it is here that many come unstuck.

However, while carbon emissions in supply chains can be as much as four times those of direct operations, carbon emission savings here can be made with little or no cost – making it a real shame that inventory management is so often overlooked.

Inventory optimisation can directly help reduce carbon emissions. Analysing data to create better forecasts, managing the supply chain more efficiently (e.g. by ordering full truckloads or combining freights) as well as becoming more agile to react faster to the market are all ways that will help you to reduce your business’ carbon footprint.

Here are just a few ways drone technology and automation can help.

Forecasting

Accurate forecasting helps companies to make sure the right products are available at the right place at the right time – but this fundamental task causes headaches for inventory and supply chain managers due to the ease with which inaccuracies can be made in manual stocktakes.

Robust forecasting helps supply chain teams to detect trends, seasonality, and volatility, and using drones can not only increase the accuracy of inventory counts, but also the frequency with which they can be carried out.

More accurate forecasting can help reduce the carbon emissions in several ways, depending on industry.

- Perishability is a big risk in the food industry, with a major cause of carbon emissions coming from wasted food that’s outlived its shelf life. Being able to run accurate stocktakes at the necessary frequency will ensure food warehouse operations are running at peak efficiency and accuracy.

- The fashion industry usually comes with long lead times and short product life cycles as new items are introduced seasonally. Unsold stock that is still available even after heavy discounted needs to be destroyed, but if seasonal patterns and demographic figures, such as size curve distributions per store, are all taken into account, it is still possible to develop accurate forecasts. As well as not needing to destroy unwanted stock, fashion warehouses can also use technology to better optimise stock allocations across the stores to reduce overproduction and waste.

- Retail outlets often struggle to ensure the right stock is available at the right place, at the right time, with incorrect items needing to be discounted, stored somewhere else (in the case of seasonal items) or destroyed.

- In the manufacturing sector, limited production capacity means accurate planning is critical. A robust forecast based on future sales can ensure the correct raw materials are purchased – eliminating unnecessary transport and production costs.

Inventory Optimisation

While forecasting helps avoid waste ahead of time by eliminating incorrect and unnecessary stock purchases, inventory optimisation is another important way to cut carbon emissions.

For example, it may be optimal to bundle products with other suppliers to fill a container and order weekly – or you may be better served by ordering full shipments on a less frequent basis.

There are plenty of ways you can optimise your inventory, but doing so relies on having an accurate picture of the comings and goings of your warehouses. Without a clear understanding of your stock levels, finding the best ways to reduce your carbon emissions is impossible.

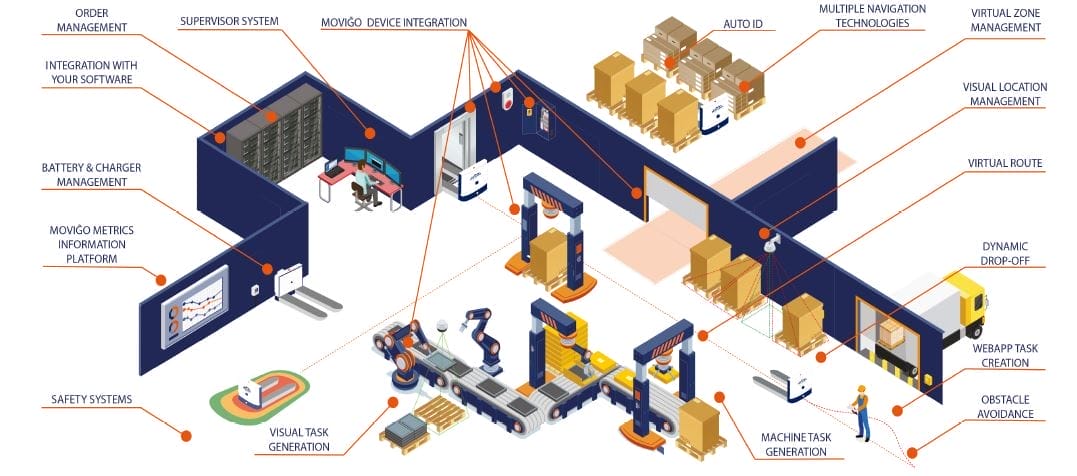

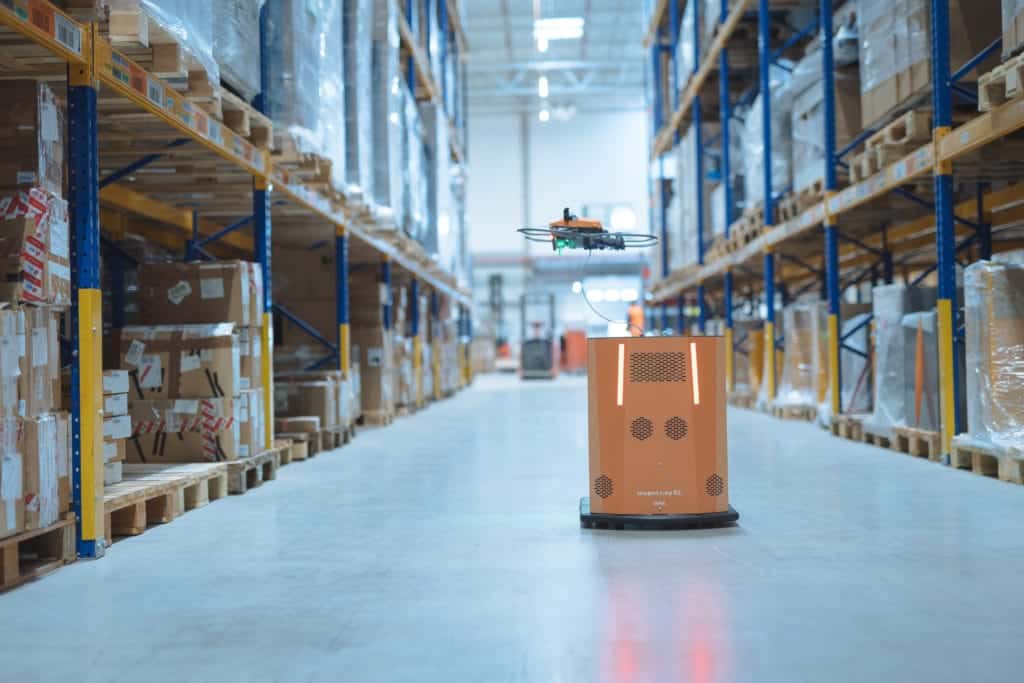

Automated inventory management, like the unique inventAIRy from doks.innovation, helps warehouse operations carry out more stock takes at higher accuracy levels than ever before. This, in turn, helps better plan both deliveries and exports, leading to more efficient purchasing and storage.

In summary…

If you run a warehouse, your emissions will form an important part of Scope 1 and 2 requirements. If you use warehouses as part of your logistics and supply chain, ensuring they are making efforts to reduce emissions is part of your Scope 3 commitments. Whichever way you look at it, warehouses need to start on this journey – and inventory control automation is a great way to do that.

Not only does it give a much clearer picture into potential inefficiencies within the supply chain, but a solution like inventAIRy XL has other benefits over people and other drone solutions – including longer battery life and the ability to operate in the dark (so you can stop wasting electricity!).

Like what you’ve read so far? There’s lots more in our logistics whitepaper. Get your free copy at the link below.

Revolutionise your warehouse

See our exclusive whitepaper to find out how you can enhance your warehousing and logistics operations