The threats and challenges facing logistics and manufacturing sectors.

Loss of labour, increased costs, greater competition and higher injury risks – these are just some of the key threats and challenges facing logistics and manufacturing sectors.

See how an inventory management solution can help you overcome these issues.

There’s no escaping the fact that the manufacturing industry is a key part of the UK economy – employing 2.7 million people and accounting for 45% of the UK’s exports in 2021. The number of businesses falling under the logistics umbrella, meanwhile, was 88% higher in 2021 than it was a decade earlier.

But while those stats may show two industries in rude health, scratch beneath the surface and we see a series of threats that, if left unaddressed, could have dire consequences.

Labour availability and quality trending down

The manufacturing and logistics industries employ almost 4 million people between them – more than 10% of workers in the UK. But as with many other industries, businesses in these sectors are facing chronic staff shortages.

A City & Guilds report estimated the logistics sector faced a 400,000 staff shortfall by 2026, while the Chartered Institute of Logistics and Transport reported that 80% of businesses in the sector are reporting understaffing.

It’s not just the quantity of staff that’s causing problems – it’s the quality too. According to research published in Statista, 3PL providers listing their top challenges said finding, retaining and training staff was a very real issue (73%, along with 47% of global shippers). The issue is so acute that UK Warehousing Association’s put the theme of staff shortages at the centre of its National Conference.

One thing the global pandemic showed us was just how much could be ordered online. This caused a perfect storm – a huge spike in demand just as labour shortages started to bite.

Customer expectations are rising

One thing the global pandemic showed us was just how much could be ordered online! What once was used for impulse purchases or last minute birthday presents was suddenly relied upon for everything – the weekly shop, clothing, essential work items, all ordered online, and all expected in a very short delivery window.

This caused a perfect storm – a huge spike in demand just as labour shortages started to bite. According to research published in Statista, warehouses asked to list the impact of COVID-19 on their operations named increased demand and expectation as four of the top five (with staff issues being the fifth):

- Dealing with increased customer expectations (eg same or next day delivery): 35%

- An increased volume of eCommerce orders: 35%

- Fulfilling more orders, faster and at lower cost: 34%

- Reducing order errors / improving order accuracy: 25%

Health & Safety risks

The health and safety of workers has, rightly, become paramount in the past couple of decades. Better logging of incidents and increased fines have helped raise awareness of the many risks employees face across a range of industries, prompting employers to look at ways to cut down on dangers.

So what risks are companies in the logistics sector facing? Falls from height are responsible for just under 30% of fatalities in 2019/20, while being struck by a moving vehicle accounted for 20%. Moving machinery, meanwhile, was responsible for 11% of fatalities. That’s across all industries, but they are undoubtedly the risks that those working in the logistics sector are most at risk from.

To add to that, in 2018/19 there were major non-fatal injuries from:

- Handling, lifting or carrying (14,895)

- Struck by moving or falling objects (7,753)

- Falls from a height (4,046)

- Struck by a moving vehicle (1,455)

Enter automation

Fortunately, there is a solution to the above problems in the form of automation. From inventory counts through to pallet transport and lifting, automation can fill in staff gaps, increase efficiency, remove risk and save money.

But while automation brings undoubted benefits to logistics operations, many companies are slow to embrace these advantages. According to research published in Statista the top barriers to automation and robotics implementation are:

- RoI calculations (40%)

- Understanding when / how to start (35%)

- Finding the right supplier (11%)

- Interruption to current services (10%)

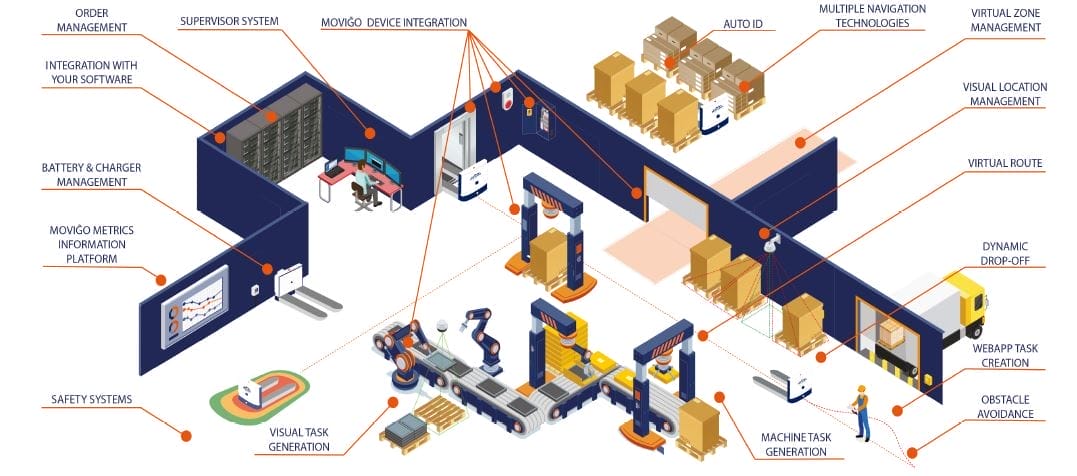

All very valid concerns, but fortunately ones we can resolve. Our “warehouse 4.0” project was created to address those concerns mentioned above, by giving our customers access to an end-to-end service that not only identifies the bottlenecks and inefficiencies associated with existing, often outdated inventory control processes, and addresses those issues with the implementation of technologies developed specifically for inventory control automation.

As an example, the inventAIRy XL solution typically delivers an RoI in under a year, while bringing other benefits like increasing inventory accuracy, freeing staff up for more productive jobs (or, indeed, filling in staff shortage gaps). One early adopter was able to complete a fully automated stock check of 16,000 pallet locations every 7 days – versus the 3-4 weeks it would have taken previously.

As for interruption to the current services, there’s no need for logistics operators to worry. In the past, setting up an automation programme would have involved a proof of concept lasting several months. Warehouse drones, meanwhile, used to involve significant cost, disruption and infrastructure changes (and for certain systems from other suppliers, still do). That meant significant time and effort investments that busy warehouses couldn’t commit to – especially in the face of staff shortages and increased customer demands. The range of warehouse 4.0 solutions from RAWview have all been chosen with ease of setup as a key feature, meaning logistics providers can enhance their warehouses with the minimum of interruption.

We work with our customers to create a bespoke suite of products designed to resolve their pain points in the most efficient way possible. A discovery call can help accurately predict the RoI period, and once we get the go ahead we can have them up and running quickly, with the minimum of disruption to your business or infrastructure.

Choose automation, remove the threats

No one claims there aren’t real challenges and threats facing the logistics sector. But we do claim there are solutions – and that we can provide them.