Meet the next level of warehouse drones

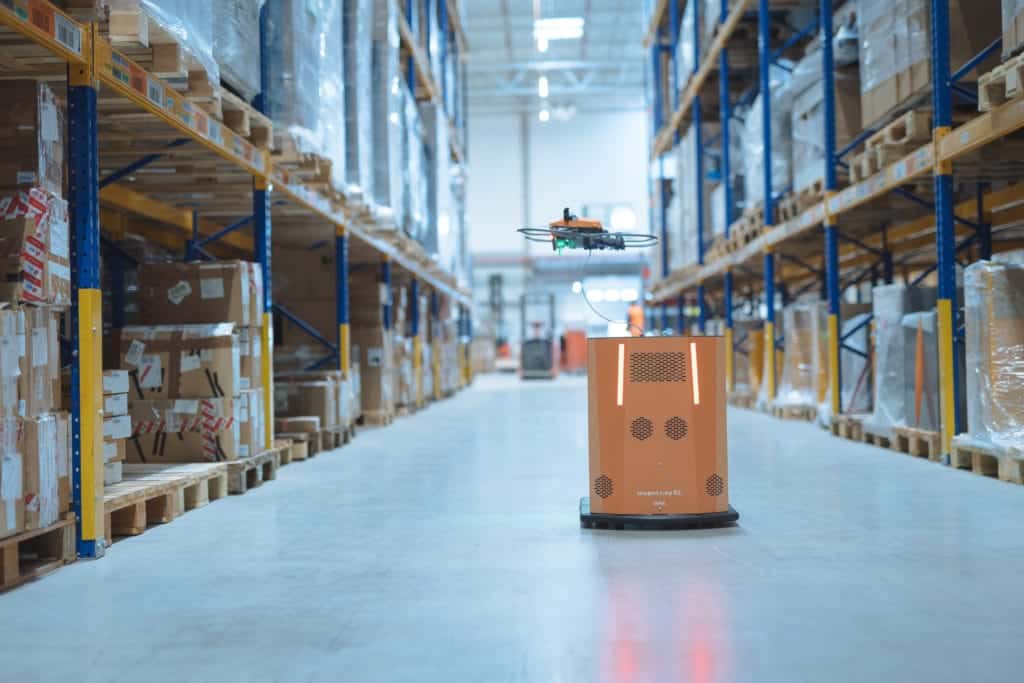

Automating your warehouse inventory counts can help save time and money, increase accuracy and enhance safety. Let us show you why inventAIRy XL is the best solution to help you reach the next level in your warehouse operations.

TABLE OF CONTENTS

Inventory drones are best suited to facilities that suffer either from inaccurate inventory records, or who find staying on top of inventory with regular manual counts a significant cost implication.

The possibilities for warehouse efficiencies introduced by drones are many and varied, from physically moving items around through to the arduous and time-consuming inventory control tasks (which is where we come in!).

Until now, drone solution providers tried to take technology that worked brilliantly outside and repurpose it for the warehouse – but poor GPS signals, moving obstacles, low ceilings and limited room all mean this translation has presented some challenges.

But that’s a thing of the past thanks to doks.innovation’s inventAIRy XL which overcomes the traditional challenges of drone-based inventory control, and also vastly outperforms other drone-based inventory counting solutions.

Flight endurance

The drones currently in use in warehouse and logistics typically have a maximum flight endurance of just 20 minutes before the battery needs to be swapped out and recharged by a member of your team.

inventAIRy XL, on the other hand, has a huge 5 hour battery life, and automatically returns itself to its docking station to recharge when required. And when it’s recharged, it can pick up right where it left off.

Why is this such a game-changer? Well the 5 hour endurance means a single inventAIRy XL system can scan up to 2000 pallet locations without any human intervention whatsoever. Compare this against its “drone-only” counterparts, which can scan just 120 pallet locations before human intervention (battery swapping) is required.

To put it another way: for a drone-only system to match the autonomous workrate of a single inventAIRy XL system, you would need to deploy at least 16 drones, working simultaneously in your facility. Obviously, this is not feasible for any warehouse, so the workaround is to deploy fewer drones and rely on humans to carry out multiple battery swaps throughout the mission – far from an “autonomous” approach.

Battery longevity

The short battery endurance isn’t just a strain on human resources and your energy bill – it’s a strain on the batteries themselves, too. To match inventAIRy XL’s impressive 5 hour endurance, drone-only equivalents are typically supplied with 4 batteries. Two of these would be charged three times during a 5 hour mission, while the others would be charged twice.

In isolation that may seem nothing more than an inconvenience (though we’d say a pretty major one if your goal is to automate inventory counts!), but when you start to add the figures up it raises some alarming questions.

To match a 5 hour run time every day – something that’s more than achievable with the inventAIRy XL – those batteries would be getting re-charged between 56 and 84 times PER MONTH!

This raises serious question marks over battery longevity. Most drone manufacturers rate their batteries for around 200 charging cycles before their efficiency and reliability takes a nosedive.

With this in mind, you can expect to be buying new batteries and disposing of old ones every 2 to 4 months. This is both expensive and extremely bad for the environment!

GPS signal

In outdoor use cases, automated drones typically navigate via GPS. That’s fine in quarries, on construction sites or for security patrols, but the lack of GPS signal indoors renders this navigation technique impossible.

The general alternative was to implement complex software algorithms and physical ArUco markers, and use the drones’ on-board camera to tell it where it is in the warehouse and where it needs to go next – but this solution not only requires changes to warehouse infrastructure (accurate positioning of the markers), but also mean the drones can’t operate in the dark. So even if the drones didn’t require regular human intervention to switch out the batteries, it still means it can’t function when the warehouse is unsupervised.

inventAIRy XL, on the other hand, operates by following a pre-programmed route (think those Big Trak toys from 1979). Combined with the long battery endurance, when we say it can be left to do its thing when everyone’s gone home, we mean it. It even has a built-in light on the scanner, so your warehouse can be completely shut down at night – saving on power costs and reducing your carbon footprint.

inventAIRy XL – the next level of inventory control

Drones absolutely have the potential to transform the way warehouses operate, but limited battery endurance and longevity, and the need for human intervention mean traditional drones aren’t ready to make that transformation.

That’s why we believe inventAIRy XL offers a compelling set of arguments, bringing a host of features that elevate above the other options and help truly make a difference to warehouse operations.

Interested in finding out more? For more information on the solution, see your potential savings, or to arrange a Proof of Concept, see our Warehouse page.

Like what you’ve read so far? There’s lots more in our logistics whitepaper. Get your free copy at the link below.

Revolutionise your warehouse

See our exclusive whitepaper to find out how you can enhance your warehousing and logistics operations

You might also be interested in…