How drones can optimise inventory management in 2021

Online shopping has risen exponentially in recent years – a trend made more pronounced by the COVID-19 pandemic. With an increase in eCommerce spend – coupled with new innovations like same-day delivery – has come a greater demand for warehouse space in urban areas.

When you also factor in an increased inventory velocity to keep up with this growth, it’s clear why space utilisation has become an important KPI at large warehouse facilities.

Inventory drones are best suited to facilities that suffer either from inaccurate inventory records, or who find staying on top of inventory with regular manual counts a significant cost implication.

Negative impact of poor space utilisation:

The operating metrics of warehouses have been greatly impacted by storage practices; it is vital to allocate the optimal proportion of storage space to the most valuable and high-velocity warehouse inventory, and a failure to do so can result in:

- Stockouts, or out-of-stock (OOS) events, where inventory items have been consumed and orders can’t be fulfilled

- Overstocking, created by poor management of stock demand or material flow. It goes without saying that excessive stock results in margin erosion due to the capital tied up, as well as wasted storage space.

- Dead stock, where unsold items end up lying in the warehouse for a long time, taking up valuable space and potentially resulting in obsolescence, spoilage or theft.

Increasing operational efficiency in the warehouse

There are numerous techniques to optimise warehouse space for inventory storage, including:

- Real-time data: Real-time inventory updates help to improve inventory planning.

- Very Narrow Aisles / Vertical Maximisation: By reducing the width of the aisles, increasing the height of racks, or both, warehouses can boost the number of pallet locations from the same floor area.

- Put-away Time: Minimising the distance and time it takes for products to travel the path from receiving to storage.

- Pick Paths: Identifying the optimal path depending on each product’s shipping frequency.

However, those methods require changes to existing operational processes or the warehouse infrastructure itself. Despite the obvious benefits these changes will bring to a warehouse’s operational efficiency in the long run, they are often not implemented.

Fortunately, there is now another way to ensure optimum inventory management

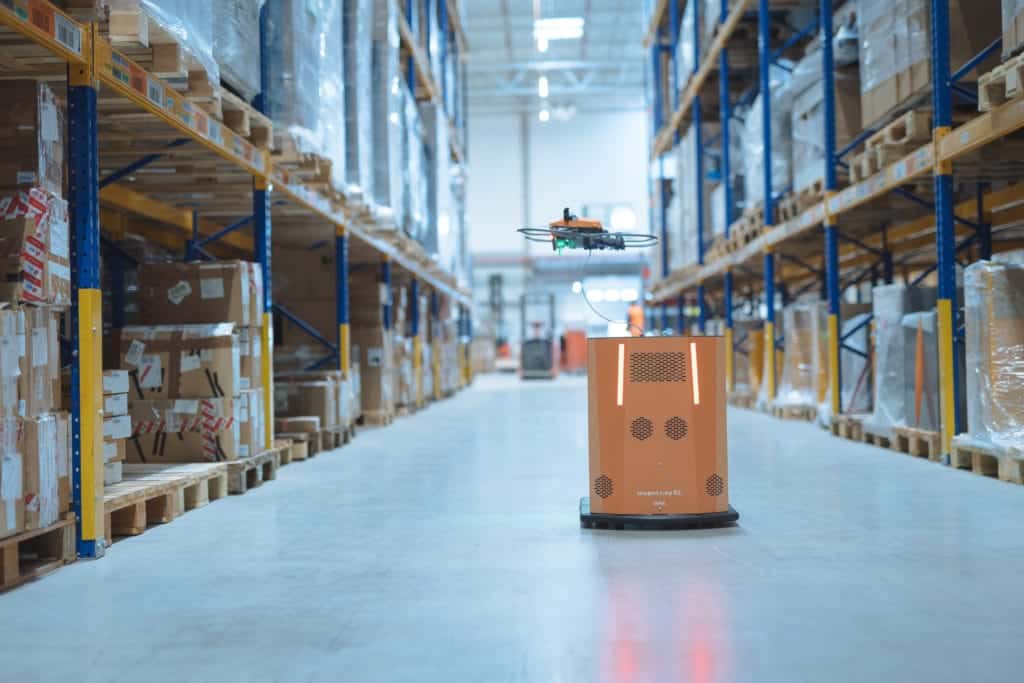

Inventory drones to optimise space

Autonomous drones can be implemented in warehouses with minimal impact to the existing infrastructure. Once in place, they can be used for:

1. Empty-bin detection

A solution like the inventAIRy XL can be deployed in a few clicks to validate empty bin locations across all aisles. This – in turn – helps to reduce wasted time during putaway.

2. Putaway audits

Besides cycle counting, warehouse operators can run drone missions to check the accuracy of putaways. This dramatically reduces the time spent searching for misplaced stock.

3. WMS Integration

Compatibility with existing WMS data enables near real-time variance analysis between the pallet inventory data collected by the drone(s) and what’s recorded in the WMS. This makes identifying and resolving inventory discrepancies faster and more straightforward than ever before.

Other useful features of inventory drones include the ability to track down inventory to a specific pick location and also provide image visibility of inventory across multiple warehouse locations.

4. Cost Mitigation

Incorrect shipments, inaccurate inventory counts and human error in pick and put-aways all take their toll on a warehouse operation’s bottom line.

The inventAIRy XL solution working in harmony with the WMS can address the inefficiencies and financial losses associated with inaccurate inventory counts and human errors, quickly and cost-effectively. Optimising warehouses with aerial inventory automation can allow companies to make the best possible use of expensive real estate and the staff that operate it.

Want to find out more?

If you’re ready to revolutionise your warehouse operation with automated drone, get in touch to discuss your exact requirements in more detail.

Like what you’ve read so far? There’s lots more in our logistics whitepaper. Get your free copy at the link below.

Revolutionise your warehouse

See our exclusive whitepaper to find out how you can enhance your warehousing and logistics operations