Unlocking Efficiency: A Comprehensive Guide to Drones in Inventory Management

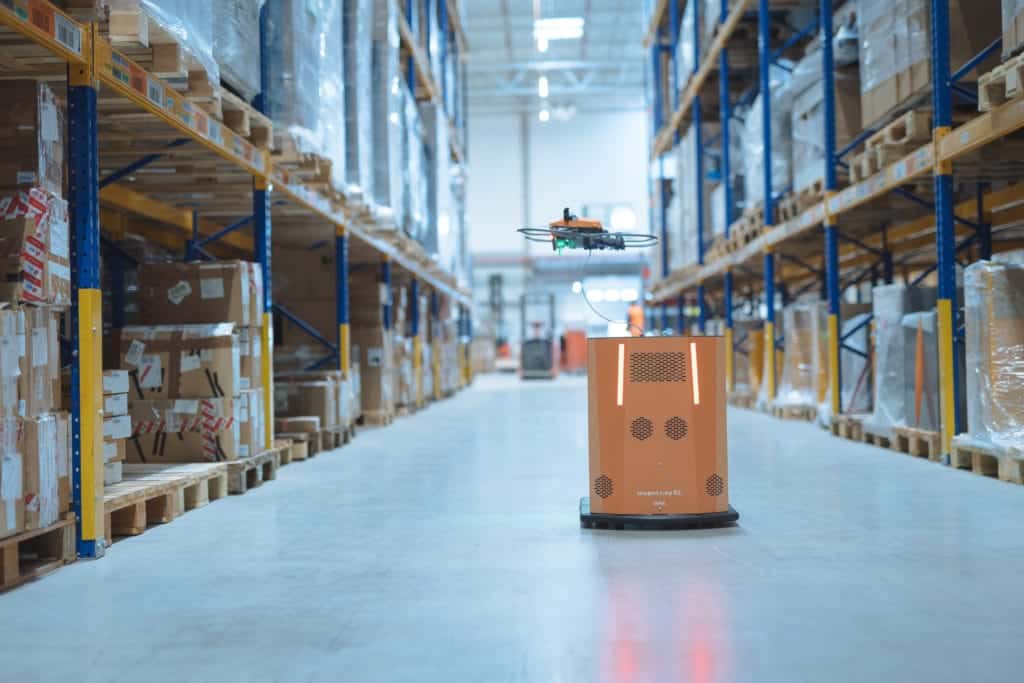

As many warehouses expand in size, and the need for efficiency increases with the continued rise of eCommerce, businesses are incorporating automation and robotics into their operations.

As part of this move towards automation, drones are increasingly used in the logistics sector, particularly within warehousing operations, such as inventory checks and intra-logistics.

Here, we look at the applications of drones in warehouses, as well as the benefits of using drones in this environment.

Benefits of using drones in warehousing

The use of drones in warehousing offers several benefits, including:

Accessibility

Drones can make certain warehousing tasks more accurate and accessible. Specific processes, such as the cycle counting of inventory can be difficult to complete manually, due to being challenging to reach or access, using drones resolves this common problem.

Affordability

The use of drones is also affordable, eliminating the labour and equipment costs involved in completing manual warehousing roles. While there is a cost involved in buying the drones themselves, the savings made elsewhere deliver a sizeable return on investment (ROI), with a short payback period, often as short as under 12 months.

Inventory drones are best suited to facilities that suffer either from inaccurate inventory records, or who find staying on top of inventory with regular manual counts a significant cost implication.

Possibility for workers to upskill

Scalability

Driven by software, drone solutions are scalable and can be customised to meet the warehouses’ specific requirements.

Safety

Drones can help improve warehouse safety, reducing the need for workers to operate at height and use hazardous machinery such as forklifts. Rather than requiring workers to reach items that are stored high up, the drone can be used to access them instead.

Automation

Drones can hover and fly autonomously. So, using software-based drones, it is possible to automate warehousing tasks, such as scanning of pallet barcode labels and reconciling that data against WMS/ERP inventory records. This improves productivity and accuracy, removing the need for human input in the process.

In addition to this, drones can also be used to gather image data from each pallet position, which can be analysed to enable faster operational decisions, as well as also providing valuable information during year-end audits.

Application of drones in warehouses

Drones can be used in several warehouse management applications, including:

Inventory control

This is the most common use of drones in warehousing.

Drones can be used to safely carry out inventory counts in warehouses. Their application is used, but not limited to:

When inventories are carried out and managed manually, teams must walk round the warehouse, scanning and counting items. The process can be slow, labour-intensive, dangerous, expensive, and prone to inaccuracies.

Autonomous drones for inventory management, on the other hand, can increase inventory accuracy, while reducing labour costs and minimising health and safety risks amongst the workforce. Drone inventory is 3x faster and 3x more cost effective than manual counts.

It also means that workers can continue with their daily duties, rather than being pulled away to carry out inventory-related tasks.

Find out how we’re helping warehouse operators to deploy a Fully autonomous drone application that revolutionises inventory control processes:

Or get in touch:

Find out more about the application of drones in warehouses by:

- Emailing us at [email protected]

- Calling us on 0203 488 4071